Polyurethane Vibrating Screen Deck Is The Main Working Sieve Deck On The Vibrating Screen Machine, Which Is In Direct Contact With The Screening Medium. It Is Used For Screening Solid Particles Of Different Sizes, Or Separation Between Solid Particles And Liquid. Therefore, The Wear Resistance Is The Core Performance Of The Screening Deck, Followed By The Elastic Performance, Which Mainly Plays The Role Of Earthquake Resistance, Buffer, Decompression And So On.

Polyurethane Screen Deck Of The Vibrating Screen Can Be Composed Of Single Layer Or Multi-Layer To Form The Main Parts Of The Vibrating Screen. Different Kinds Of Mixture Are Divided Into Different Particle Size Grades To Meet The Requirements Of Certain Beneficiation Process. Polyurethane Vibrating Screen Is Widely Used In Non-Ferrous Metals, Ferrous Metals, Coal, Road Construction And Other Industries.

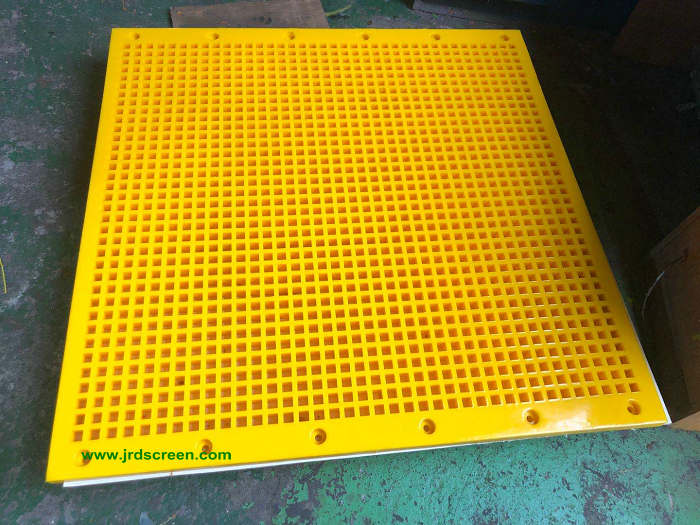

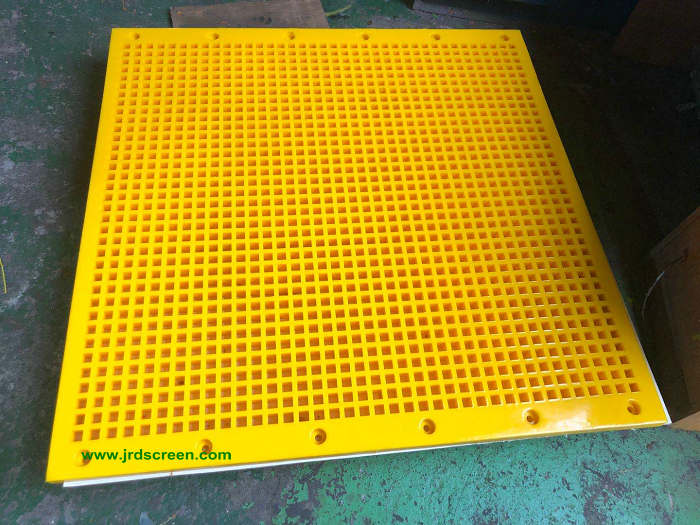

Our Urethane Screen Deck Can Be Used For Different Types Of Roller Screen, Self Centering Vibrating, Heavy-Duty Vibrating, Etc. Polyurethane Sieve Deck Is Inserted Into The Metal Frame With The Same Aperture, Uniform Distribution, High Level Wear Resistance And Low Noise Effect. It Can Be Well Applied To The Classification System Of Metal Mine And Non-Metal Mine.

Structural Characteristics And Physical Requirements

Our Company Can Design And Manufacture Different Products According To Different Requirements Of Users (Different Specifications, Different Purposes) To Meet Various Operating Conditions.

Our Urethane Sieve Deck Uses Steel As The Frame And Special Polyurethane As The Working Surface. This Kind Of Screen Deck Has Many Advantages And Is Suitable For Heavy Vibration Equipment In Mining, Metallurgy, Coal Mine Screening, Building Materials And Other Industries.

The Rigid Polyurethane Frameless Vibrating Screen Deck Is Made Of Pure Polyurethane, Which Enhances The Overall Wear Resistance Of The Vibrating Screen Deck. It Is Fixed By Bolts And Nuts To Provide a Strong Guarantee For The High-Strength Wear Working Environment.

Advantages And Characteristics

In The Process Of Screening, Due To The Friction Between Screening Materials And PU Screen Deck, There Will Be Serious Wear On The Deck. Compared With The Steel Deck And Other Materials, The Polyurethane Vibrating Screen Deck Produced By Our Company Has The Following Advantages:

1, Light Weight And Low Energy Consumption: The Density Of Polyurethane Is Only One Sixth Of That Of Steel Material, Which Greatly Reduces The Load Of Vibrating Screen Machine.

2, High Damping Capacity, Reduce Noise: Smooth Surface, Reduce Friction, Soft Material, No High-Strength Collision Noise.

3, New Structure, Easy To Assemble And Disassemble: The Overall Design Has Fully Considered The Replacement And Use Requirements Of The Owner, Which Is Very Easy To Disassemble, Install And Replace.

4, Good Elasticity Makes The Material Bounce More Frequently And The Screen Efficiency Higher: Polyurethane Elastomer Itself Has Strong Elasticity, Rebounds The Material And Reduces The Impact Force; The Inclusion Of Mesh And Material Removes The Adhesion Phenomenon Of The Material In The Vibration.

5, The Holes Diameter Of The PU Sieve Deck Will Be Deformed Within a Certain Range, Thus Reducing The Possibility Of Blocking The Screen With Materials: The Polyurethane Vibrating Screen Deck Has a Very Good Ductility, Which Can Avoid The Inclusion Of Locked Materials.

6, In The Process Of Pressure Forming, Different Materials Can Be Used To Frame And Extend The Service Life: Usually The Combination Of Polyurethane And Steel Framework.

7, According To The User's Requirements And Service Conditions, The Design Life Of Vibrating Sieve Deck Can Be More Than 3000 Hours.